In the realm of occupational safety, personal protective equipment (PPE) for the eyes is a critical line of defense against workplace hazards. Understanding and complying with PPE eyewear regulations is not just a legal requirement but a fundamental aspect of maintaining a safe work environment. This article delves into the various facets of PPE eyewear compliance, emphasizing the importance of hazard assessment, employee training, and adherence to standards to ensure the safety of workers.

Key Takeaways

- Conducting comprehensive hazard assessments is essential for selecting the appropriate PPE eyewear that meets ANSI Z87.1 standards.

- Creating a safety-conscious culture enhances compliance and encourages workers to take responsibility for their eye protection.

- Employee training on OSHA standards and proper PPE usage is crucial for preventing workplace eye injuries.

- Regular inspection, maintenance, and documentation of protective eyewear are vital for sustaining PPE effectiveness and compliance.

- Adhering to OSHA standards for eye protection is imperative to reduce the risk of injuries and maintain a safe and productive workplace.

Comprehensive Hazard Assessment and PPE Selection

Identifying Workplace Eye and Face Hazards

The foundation of eye safety in the workplace begins with a comprehensive hazard assessment. Employers are tasked with identifying potential risks that could lead to eye or face injuries. This crucial step informs the selection of appropriate protective eyewear that aligns with the identified hazards.

- Chemical splashes from industrial processes

- Flying debris from machining operations

- Dust and other particulates in construction or woodworking

- Radiation exposure in medical or laboratory settings

- Intense light from welding or laser operations

Once hazards are identified, it’s essential to choose protective eyewear that meets the rigorous ANSI Z87.1 standards, ensuring workers are shielded from the specific dangers they face. Regular updates and reassessments of the workplace hazards are necessary to maintain a safe environment and adapt to any changes in operations or procedures.

It is not just about compliance; it’s about ensuring that every worker goes home safely each day. Creating a culture of safety and vigilance is as important as the protective equipment itself.

Choosing PPE That Meets ANSI Z87.1 Standards

When selecting personal protective equipment (PPE) for the eyes and face, it is crucial to ensure that the products meet the American National Standards Institute (ANSI) Z87.1 standard. This certification indicates that the eyewear has been rigorously tested and is capable of providing adequate protection against common workplace hazards such as impact, penetration, radiation, and chemical exposure.

To comply with OSHA’s eye protection guidelines, employers must provide PPE that adheres to these standards. The following list outlines the key features that ANSI Z87.1 compliant eyewear should possess:

- Adequate impact resistance

- Protection from UV and IR radiation

- Resistance to penetration

- Coverage for the full eye and surrounding areas

- Compatibility with prescription lenses

It is essential for the safety and well-being of employees that all protective eyewear not only meets ANSI Z87.1 standards but also fits properly and is comfortable for extended wear. This ensures both compliance and the willingness of employees to use the equipment consistently.

Regular checks for any signs of damage or wear are necessary to maintain the integrity of the protective eyewear. If any defects are found, such as cracks or deformities on the lenses, or if the strap is not in good working condition, the PPE must be replaced immediately to ensure ongoing protection.

Regular Site Evaluations for PPE Necessity

Regular site evaluations are essential to determine the ongoing necessity and adequacy of PPE, including eyewear, in the workplace. These evaluations help identify any changes in work conditions that may require different or additional protective equipment. It is not enough to provide PPE; it must be the correct type and fit for the task at hand.

- Check work sites regularly for the need for PPE.

- Ensure PPE provided meets established safety standards, such as ANSI criteria.

- Train employees on proper use and maintenance of PPE.

- Conduct regular inspections to assess the condition and compliance of PPE.

Accurate PD and SH measurements are crucial for prescription eyewear and PPE. Optigrid revolutionizes optical measurements, ensuring optimal vision correction and safety compliance.

By maintaining a proactive approach to PPE management, organizations can not only comply with regulatory requirements but also foster a safer work environment. This involves not just the initial provision of PPE but also ongoing assessments and updates as necessary to keep pace with any changes in the workplace or in safety regulations.

Fostering a Culture of Safety and Compliance

Encouraging Worker Responsibility for Eye Protection

Creating a culture of safety within the workplace is a critical step in reducing eye injuries. Workers must recognize their role in maintaining their own safety and be proactive in using the protective eyewear provided. This not only involves wearing the equipment but also being vigilant about its condition and suitability for the tasks at hand.

- Encourage workers to report damaged or ill-fitting eyewear immediately.

- Remind employees to perform a quick check of their protective gear before each use.

- Foster a team environment where workers feel comfortable reminding each other about eye safety.

By instilling a sense of personal responsibility, employees become active participants in their own protection, leading to a safer and more compliant workplace.

Regular training and open communication channels can further empower workers to take charge of their eye safety. It’s essential for employers to provide clear guidelines and support for employees to follow through with these responsibilities.

Creating Safety Protocols and Best Practices

Developing robust safety protocols is essential for minimizing risks and ensuring a safe working environment. Best practices in safety protocols not only protect employees but also enhance overall productivity.

- Enforce standardized safety protocols across teams and sites.

- Conduct regular training sessions for staff on the proper use of safety equipment.

- Establish maintenance protocols and routine inspections to ensure equipment is in optimal condition.

- Mitigate risks with comprehensive risk assessment templates and plan corrective actions promptly.

By fostering a proactive approach to safety, organizations can significantly reduce the likelihood of accidents and ensure compliance with regulatory standards. Creating a clear set of guidelines and expectations around PPE eyewear use is a cornerstone of this approach.

Promoting Vigilance and Ongoing Safety Education

In the realm of workplace safety, continuous education is key to maintaining a vigilant and informed workforce. Safety education should not be a one-time event but an ongoing process that keeps pace with the evolving nature of work environments and the introduction of new equipment or procedures.

By fostering a culture of learning, employees are better equipped to identify and address potential safety concerns, contributing to a safer work environment.

To ensure that safety education is effective and retains its relevance, it is essential to incorporate a variety of strategies:

- Regular safety meetings to discuss new hazards and protective measures

- Updates on the latest safety protocols and compliance requirements

- Hands-on training sessions to reinforce proper PPE usage

- Distribution of educational materials and resources

Optigrid, for instance, automates data entry and lens fitting for PPE eyeglasses, enhancing not only safety and compliance but also operational efficiency. Such technological advancements should be included in safety education to keep employees abreast of the tools that can aid in their protection.

Employee Training and Engagement in Eye Safety

Educating Workers on OSHA PPE Standards

Understanding and adhering to OSHA PPE standards is crucial for ensuring workplace safety. Employers are mandated to provide comprehensive training on the proper use, maintenance, and disposal of PPE. This training should cover the types of equipment needed for specific tasks, their limitations, and the importance of proper fit.

It is not only about providing the necessary equipment but also ensuring that workers are fully equipped with the knowledge to use it effectively.

To facilitate this, a structured approach to education can be adopted:

- Familiarize employees with OSHA regulations regarding PPE.

- Demonstrate the correct use and fitting of various types of PPE.

- Discuss the maintenance, cleaning, and inspection routines.

- Outline the procedures for reporting damaged or inadequate PPE.

Employers are responsible for the costs associated with PPE required to comply with OSHA standards, emphasizing the importance of proper PPE management to avoid unnecessary expenses.

Training on Proper Use and Maintenance of Protective Eyewear

Proper training in the use and maintenance of protective eyewear is a critical component of workplace safety. Employees must understand not only the importance of wearing eye protection but also how to ensure their eyewear is in optimal condition. Regular inspection for damage and cleanliness is essential to maintain the protective qualities of the eyewear.

- Employees should be instructed on how to inspect their eyewear before each use.

- Training must include proper cleaning techniques to prevent damage to lenses and coatings.

- Workers need to know the correct method of storing eyewear to avoid unnecessary wear and tear.

It is imperative that all employees are proficient in the maintenance procedures to extend the lifespan of their protective eyewear and guarantee its effectiveness.

The integration of innovative technologies such as Optigrid can enhance the fitting process of PPE, ensuring that each worker has eyewear that is not only compliant with safety standards but also tailored to their individual needs. This approach can lead to improved safety outcomes and operational efficiency.

Involving Employees in Safety Discussions and Improvements

Creating a participatory safety environment is essential for the success of any PPE program. Involving employees in safety discussions not only empowers them but also provides valuable insights into the practical aspects of eyewear use and compliance. By establishing a safety committee with representatives from different departments, organizations can ensure that all voices are heard and that safety protocols are practical and effective.

Facilitating easy reporting mechanisms is a key step in promoting employee involvement. When workers have a straightforward and non-punitive way to report hazards or suggest improvements, they are more likely to engage proactively in maintaining a safe workplace.

Regular safety meetings and open forums encourage employees to share their experiences and concerns. These discussions can lead to actionable improvements in PPE protocols and help to foster a culture of continuous learning from incidents. It is crucial to document these meetings and any decisions made, as this not only aids in accountability but also serves as a reference for future safety initiatives.

Maintenance and Inspection Protocols for Eyewear

Regular Inspection for Damage and Compliance

Regular inspection of PPE eyewear is essential to ensure that it continues to provide the necessary level of protection. Inspection protocols should be thorough, examining both the functionality and physical condition of the eyewear. This includes checking for any signs of wear, damage, or tampering that could compromise the equipment’s integrity.

Organizations must establish a systematic approach to the maintenance and inspection of safety equipment. This includes creating a detailed schedule that outlines the frequency of inspections for different types of equipment, based on manufacturer recommendations and regulatory guidelines.

It is also crucial to have a system in place for promptly addressing any deficiencies discovered during inspections. This may involve taking eyewear out of service until it can be repaired or replaced, and implementing temporary protective measures if necessary. A proactive approach to maintenance and inspection not only ensures compliance but also reinforces an organization’s commitment to safety.

Procedures for Cleaning, Disinfecting, and Replacing PPE

Maintaining the integrity of personal protective eyewear is crucial for ensuring worker safety. Regular cleaning and disinfection are essential to prevent contamination and prolong the lifespan of the equipment. It’s important to follow the manufacturer’s instructions for cleaning, which typically include using mild soap and water, and to avoid harsh chemicals that can degrade materials.

PPE should always be inspected after cleaning to ensure that it has not been compromised and is still in compliance with safety standards.

When PPE becomes damaged or no longer provides adequate protection, it must be replaced promptly. The frequency of replacement will depend on the type of PPE and its usage, but as a general rule, any signs of wear or damage necessitate immediate action. Here is a simple list of steps to ensure proper maintenance:

- Inspect PPE before and after each use.

- Clean and disinfect PPE according to manufacturer guidelines.

- Replace PPE when damaged, worn out, or non-compliant.

Adherence to these procedures not only protects the employees but also aligns with regulatory requirements, such as those set by The Joint Commission (TJC) and Occupational Safety and Health Administration (OSHA).

Documentation and Record-Keeping of PPE Maintenance

Maintaining accurate records is essential for the effective management of PPE eyewear. Documentation serves as the backbone of PPE maintenance, ensuring that all safety equipment has been inspected, maintained, and is compliant with relevant standards. These records are not only crucial for internal checks but are also indispensable during external audits and safety inspections.

Organizations should develop a systematic approach to record-keeping that includes:

- Date and time of inspections

- Condition of the PPE at the time of inspection

- Any maintenance or repairs carried out

- The individual responsible for the inspection

It is imperative to keep a historical log of PPE maintenance to track the lifecycle of each piece of equipment and make informed decisions about replacements or upgrades.

Utilizing tools like Optigrid can significantly enhance the accuracy of PPE eyewear fitting, which is a critical aspect of safety. Accurate records of these fittings ensure that each employee is equipped with eyewear that meets both safety standards and individual needs.

Adhering to OSHA Standards for Optimal Eye Protection

Understanding the Importance of OSHA Compliance

Compliance with the Occupational Safety and Health Administration (OSHA) standards is a critical component of workplace safety. Ensuring the well-being of employees is not only a legal requirement but also a moral imperative for businesses. Adherence to OSHA regulations helps to minimize the risk of workplace injuries and accidents, fostering a safer work environment.

- Employee Safety: Protecting workers from potential hazards.

- Legal Obligations: Avoiding legal penalties and ensuring lawful operations.

- Risk Management: Implementing effective safety measures and controls.

By embedding OSHA compliance into the company culture, businesses can demonstrate their commitment to safety and their dedication to their employees’ health.

Non-compliance can lead to severe consequences, including increased risk of workplace incidents and potential legal repercussions. It is essential for safety officers to understand and uphold these standards to maintain a secure and healthy workplace.

Implementing Face and Eye Protection Measures

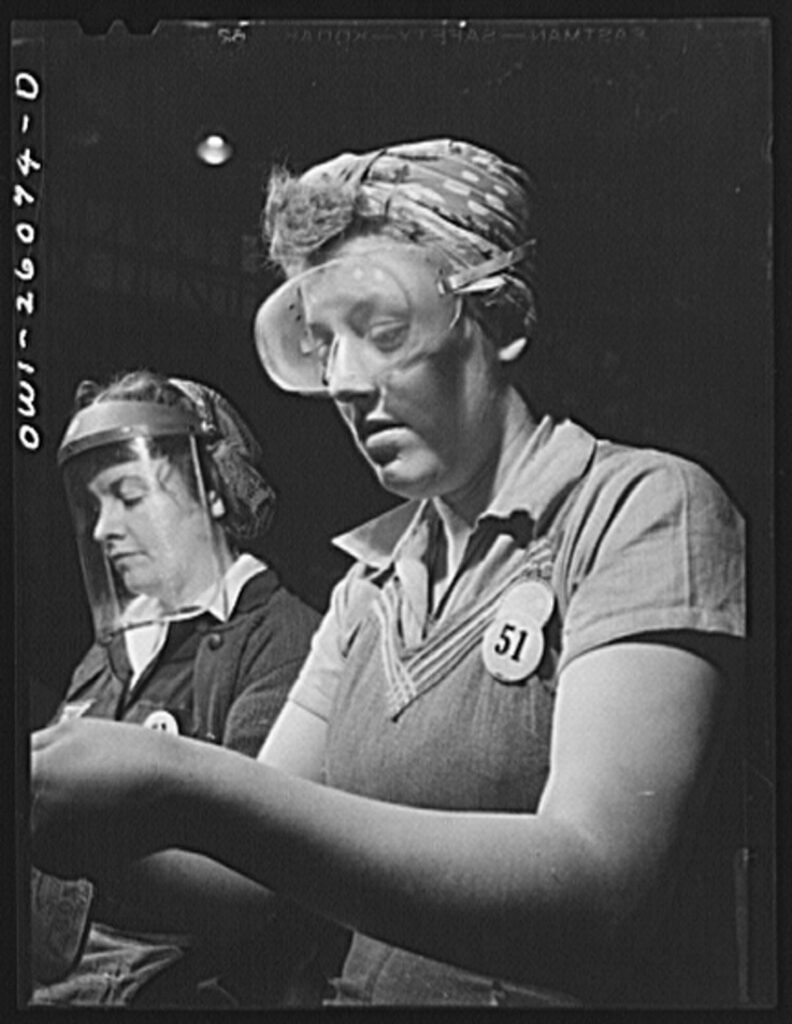

Ensuring the safety of employees in the workplace involves a critical focus on implementing appropriate face and eye protection measures. Employers are required to provide workers with protective eyewear that meets the ANSI Z87.1 standard and is suitable for the identified risks. This includes a variety of PPE such as safety goggles and face shields, which are essential for tasks that could result in eye damage or vision loss.

It is crucial for the protective equipment to fit well and be comfortable for the worker, as this encourages consistent use and helps prevent injuries.

To maintain compliance and effectiveness, the following steps should be taken:

- Conduct a thorough hazard assessment to identify potential eye and face hazards.

- Select protective eyewear that is appropriate for the hazards identified and complies with ANSI Z87.1 standards.

- Train employees on the proper use, maintenance, and limitations of their protective eyewear.

- Regularly inspect PPE for any signs of damage or wear and replace as necessary.

By adhering to these measures, employers can significantly reduce the risk of eye injuries and ensure a safer working environment.

Ensuring Respiratory Protection in Hazardous Environments

In environments where workers are exposed to hazardous substances, it is crucial to ensure that respiratory protection is not only available but also adheres to strict compliance standards. Proper respiratory PPE is vital for safeguarding against the inhalation of dangerous chemicals, dust, and particulates.

When selecting respiratory protection, it is important to consider the specific hazards present and choose equipment that provides adequate defense. Full-face respirators, gas masks, and N95 respirators are among the types of PPE that may be required depending on the risk assessment.

The following list outlines key considerations for respiratory protection:

- The PPE must conform to ANSI/ASSE Z88.2 and OSHA Standard 1910.134.

- A proper fit is essential; equipment should be tested for comfort and a secure seal.

- Regular inspections should be conducted to ensure that respirators are free from damage and in good working condition.

Maintaining a rigorous protocol for the use and maintenance of respiratory protection equipment is essential for compliance and, more importantly, for the health and safety of employees.

Ensuring the safety of your employees’ vision is not just a best practice; it’s a regulatory requirement. Adhering to OSHA Standards for Optimal Eye Protection is essential for maintaining a safe workplace. To learn more about how you can meet these standards and protect your team, visit our website. We provide comprehensive guides and resources to help you stay compliant and safeguard your employees’ eyesight. Don’t wait until it’s too late; take action now to prevent workplace eye injuries.

Conclusion

In conclusion, ensuring the safety of employees through proper use of Personal Protective Equipment (PPE) eyewear is not just a regulatory requirement but a critical component of a responsible workplace culture. Regular worksite evaluations, adherence to OSHA standards, and comprehensive employee training are essential to prevent eye injuries and maintain a safe working environment. By selecting the appropriate PPE, ensuring it meets safety standards like ANSI Z87.1, and fostering a culture of safety, employers can protect their workforce from potential hazards. It is the collective responsibility of both employers and employees to remain vigilant and committed to eye safety, adapting to evolving technologies and workplace conditions to uphold these vital safety measures.

Frequently Asked Questions

What is the ANSI Z87.1 standard for protective eyewear?

The ANSI Z87.1 standard is a set of guidelines that specify the design, construction, testing, and use of eye protection equipment to safeguard against hazards such as impact, non-ionizing radiation, and chemical exposure in the workplace.

How often should a workplace hazard assessment for PPE be conducted?

Workplace hazard assessments for PPE should be conducted regularly, as work conditions and processes can change. It’s recommended to perform these assessments annually, or whenever there is a significant change in work practices or equipment.

Why is employee training on PPE important?

Employee training on PPE is crucial to ensure that workers understand the importance of eye protection, know how to properly use and maintain protective eyewear, and are aware of the procedures to follow in case of an eye injury.

What should be included in the maintenance and inspection protocols for protective eyewear?

Maintenance and inspection protocols should include regular checks for damage, cleanliness, and compliance with safety standards. Eyewear should be cleaned, disinfected, and replaced as necessary to maintain its protective qualities.

How can a culture of safety and compliance be fostered in the workplace?

A culture of safety and compliance can be fostered by encouraging worker responsibility for eye protection, creating and enforcing safety protocols, promoting ongoing safety education, and involving employees in safety discussions and improvements.

What are the consequences of not adhering to OSHA standards for eye protection?

Failing to adhere to OSHA standards for eye protection can result in workplace injuries, legal penalties, fines, and a higher risk of liability for employers. It also compromises the safety and well-being of employees.

I am a seasoned software engineer with over two decades of experience and a deep-rooted background in the optical industry, thanks to a family business. Driven by a passion for developing impactful software solutions, I pride myself on being a dedicated problem solver who strives to transform challenges into opportunities for innovation.